Overview

Think factory machinery, security systems at homes and in offices, fire/smoke detectors, built-in motion sensors that sense human presence to switch on or switch off a light or a fan, smart television sets, smart speakers, digital assistants that monitor processes, air quality monitoring systems – IioT or Industrial Internet of Things is in the background of these, and of billions of other industrial devices.

The World Economic Forum published a report that stated, “IIoT will transform many industries, including Manufacturing, Oil and Gas, Agriculture, Mining, Transportation and Healthcare. Collectively, these account for nearly two-thirds of the world economy.” With such an enormous impact, it’s no wonder that interest in IIoT continues to keep surging. Every day, companies are realizing that digital transformation produces business results that are the most significant ones: reduced costs, time saved, and increased operational efficiency. Analysts estimate that by 2025, IIoT could generate up to $11.1 trillion a year in economic value.

To know more about UG & PG Programs, Eligibility, Admission Procedure, Fee Structure and Scholarship, please fill this request information form.

‘Efficiency’ is the keyword that distinguishes an organization that reaches great heights from an organization that just manages to survive. By improving operational efficiency with IIoT data, businesses can gain productivity, without spending on extra assets or resources. They can cut costs, automate work, reduce manual paperwork, improve safety and save time. They can make informed business decisions, based on real-time data.

The uses of IIoT systems are manifold. IIoT is very useful in tracking assets and resources. Via GPS tracking, a company can get real-time information about the location and status of a shipment, wherever it is in the supply chain. The data generated by IIoT can also spot faulty machinery before it breaks down. For example, if a freezer truck transporting ice cream is not maintaining the desired temperature, the IIoT system springs into action and notifies the people concerned who can then do the troubleshooting. Predictive maintenance not only saves time and cost but also keeps the image and reputation of the company intact.

The Industrial Internet of Things (IIoT) Engineering is a specialized branch of Engineering that trains students to deal with industrial devices that use sensors to monitor and optimize operations. Connected by a public or private network, IIoT devices capture and share data, while software analyzes this data to improve business efficiency. IIoT Engineering provides a firm foundation in the Internet of Things. It combines the elements of Electronics and Computer science, with emphasis on Internet technologies, wireless communications, sensor devices, and cloud computing.

A Sneak Peek into your Future

Today, more and more industries and companies are using IIoT systems to increase efficiency, improve safety, do predictive maintenance, cut costs and save time, thereby augmenting customer satisfaction. The Manufacturing industry has been an early adopter of IIoT - manufacturers use IIoT to enhance their processes with automation, monitor their equipment so that they can perform preventive and predictive maintenance on them, and understand customer tastes and preferences. The Oil and Gas industry is also reaping the benefits of IIoT in-plant processing, drilling operations, tank monitoring, monitoring pipe pressure and flow rates at refineries.

IIoT is taking off fast in the Construction industry, too. IIoTsystems help to boost structural integrity and quality, predictive maintenance, supply chain monitoring and worker safety.Transportation is another industry that’s catching up on IIoT. This sector uses IIoT to monitor cargo, maintain schedules, optimize fuel consumption and keep tabs onrailway tracks.

But it is not justprivate businesses that use IIoT. Manycities are aiming to become ‘smart cities’by using IIoT insmart grids that lower the stress on power grids during peak hours, in traffic and parking management, waste collection, safety in parks and gardens, air quality monitoring, and even in tourism to improve visitor experiences. With so many opportunities at hand for jacking up cities, Governments are on their way to becoming major IIoT players.

Many products are designed using IIoT. Industries use quality monitoring and management systems, attendance monitoring and management system, energy monitoring system, machine automation system, and wireless control systems. Commercial offices use IIoT for lighting control and management system, energy measurement system, etc. In Residential buildings, IIoT finds use in-home automation, lighting automation, parking automation, and water management automation. In Agriculture, it is used in inspection and monitoring of soil health, monitoring of temperature and humidity, irrigation automation, crops inspection, customized agriculture tools, etc. IIoT is used in the Energy sector too, in energy monitoring and management, on-grid and off-grid management, etc. In the medical field, it is used in wireless sensors, patient inspection automation, health monitoring, medical equipment automation, and so on. Hence, with IIoT being a booming technology, there is no dearth of jobs for IIoT engineers. A graduate engineer specializing in IIoT can find placement in so many sectors, both Private and Public.

Why a Degree in IIoT Engineering from MVJCE?

The guiding principle at MVJCE is ‘Every student has enormous potential which can be tapped and pruned, to benefit society. Hence, every student here will be personally guided by Professors who hand-hold you, right from the moment you enter the College. Moreover,

- MVJCE is one of the best colleges in Bangalore for Engineering courses.

- It ranks 8th among the top Engineering colleges in Bangalore.

- It is an autonomous institute,and hence offers a tailor-made program in Computer Science Engineering, with the ultimate goal of making every student industry-ready, at the end of 4 years of his study here.

- It is approved and recognized by all the premier educational bodies in India like AICTE, UGC, NBA and NAAC, and is also affiliated to VTU.

- It provides ample scope for ‘learning outside the classroom’ – the academic calendar is filled with Workshops, Seminars, Projects, Tech events, Guest lectures, Competitions and contests and Field trips.At such events, the students get to interact with the best in the Industry and Academia, and benefit from these interactions.

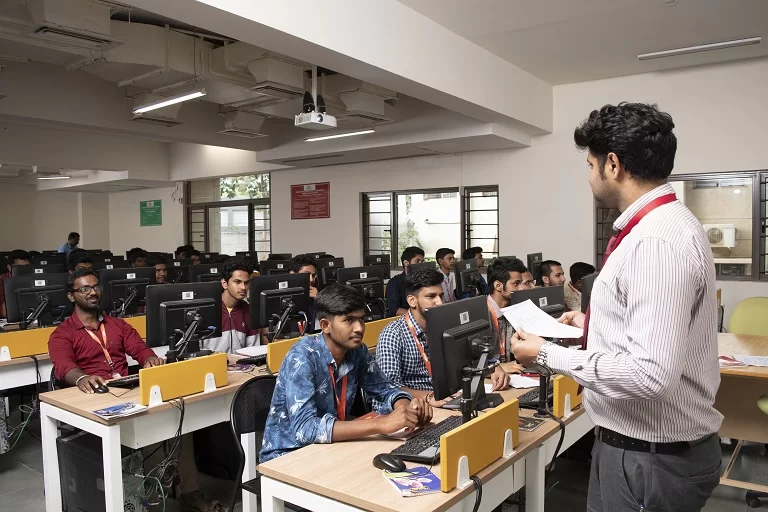

- It boasts of state-of-the-art infrastructure – modern classrooms, fully equipped labs, and a great ambiance set in 15acres of lush greenery.

- It brings to you the valuable guidance of innovative and experienced educators who will prepare you for a successful career.

- It offers a program in IIoT that combines the key elements of Electronics and Computer Science, with emphasis on Internet technologies, wireless communications, sensor devices, and cloud computing.

- It equips you with systematic professional knowledge as well as strong practical skills in the fields of embedded software development, IoT devices, and the cloud, Data Analytics, web user, and Mobile app development that provides a wide range of applications in the Internet of Things.

- It bestows on you a specialization in IIoT that is designed to enable you to build sensor network design, network planning and carry out many tasks in the various fields related to IIoT.

- It helps you gain not only a scientific and logical understanding of cutting-edge topics but also develop the employability skills required for succeeding in the fast-paced, ever-evolving technology industry.

- It offers the space and opportunity for both collaborative teamwork as well as an individual effort, thus preparing you for the road ahead.

- And it will help you get an assured placement at the end of your 4-year study, as reputed companies visit MVJCE to recruit fresh talents.

Related to Industrial IOT