A one-week AICTE Sponsored Short Term Training Programme (STTP) on Advanced Manufacturing Techniques for Medical and Precision Engineering – Phase III

| Date of the Event | 1st March 2021 to 6th March 2021 |

| Title of the Event | A one-week AICTE Sponsored Short Term Training Programme (STTP) on ‘Advanced Manufacturing Techniques for Medical and Precision Engineering – Phase III' |

| Number of Sessions | 12 |

| Resource Speaker | 5 people from Industry

7 people from Academia

|

| Organized by | Department of Mechanical Engineering, MVJCE |

Material selection and manufacturing processes are playing a critical role in today’s competitive and sophisticated precision medical manufacturing industry. There have been substantial and significant advancements in research and development of polymers, ceramics, semiconducting materials and composites, as functional materials in the field of structural, biomedical, sensor and energy applications. Similar advancements are taking place in the manufacturing processes, viz micro EDM, ECM and 3D printing.

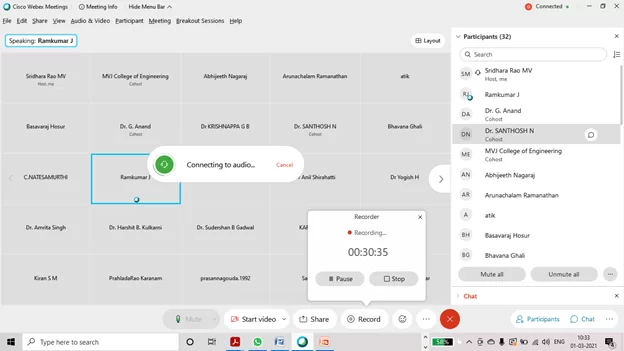

Keeping this in mind, the Department of Mechanical Engineering, MVJCE, organized a one-week AICTE Sponsored Short Term Training Programme (STTP) on ‘Advanced Manufacturing Techniques for Medical and Precision Engineering - Phase III’ from 1st March 2021 to 6th March 2021 (10.30 AM to 12.30 PM and 2.00 PM to 4.00 PM). The STTP was designed to provide insights into state-of-the-art recent trends and advancements in Precision Manufacturing techniques, developments in the medical industry, advanced manufacturing techniques that use digital data exchange, and opportunities for Research and Development. On an average, 40 participants (15 from MVJCE and 25 from outside) benefited from this short term Training Programme.

This STTP was sponsored by All India Council for Technical Education (AICTE), in association with Institution of Innovation Council (IIC) and IQAC, MVJCE.

The sessions were conducted in virtual mode, i.e online (Webex Platform), due to the COVID situation prevailing across the world.

Eminent scholars from premier academic institutes were invited to deliberate on precision manufacturing techniques for medical industry, micro machining and nano finishing techniques and digital manufacturing using data exchange.

Day 1: 1st March 2021 (Monday) – Inauguration of the STTP

Dr. Sunil Shankar Waddar, Associate Professor, Mechanical Engineering Department at MVJCE, welcomed all participants for the STTP. Dr. Rajesh Kumar Paul, Associate Professor in the Mechanical Engineering Department presented an introduction to the STTP, and requested the HoD of the Mechanical Department to deliver the Welcome Address.

Dr. Vivkekanand Huddar, HoD of Mechanical Engineering Department, MVJCE, and Convenor of the STTP welcomed the Guests of Honour, Speakers and all the participants to the STTP programme.

The Principal, MVJ College of Engineering, highlighted the relevance of the STTP in the current scenario of the industry. He stressed on the importance of advanced manufacturing in precision medical industry.

Dr. J. Ramkumar, Professor, Dept. of ME, IIT Kanpur, was the Chief Guest and he delivered the keynote address for the STTP. He highlighted the most happening areas in the years to come, viz Drones for delivery of medical equipment, Big data based medication on the daily schedule of individuals, creation of stem cells for use in the missing elements in the body, wrist watch to read the mind, appliances activation based on mental health, use of AI for cancer diagnostics, pocket ultrasonic device for scanning organs, 3D heart printing, and rehabilitation using virtual reality.

Day 1: 1st March, 2021 (Monday)

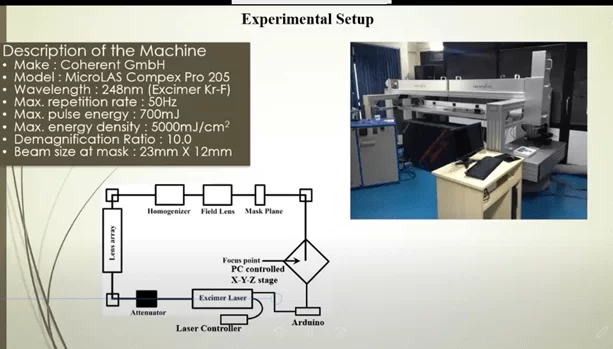

The first session on Day 1 was on the topic ’Basics of Laser Machining and its Application’, by Dr. J. Ramkumar, Professor, Dept. of ME, IIT Kanpur. Dr. Sunil Shankar Waddar introduced the Resource Person to the participants.

Current requirement of materials needs to be smart, and parts made out of them need to be as small as possible. This brings out the need for micromachining of features, and Lasers play a critical role in their creation. Starting with the basics of Laser technology, the types of Laser and Excimer Laser were all explained in detail, by the Speaker.

Day 1 Session 1 : Basics of LASER Machining and its Application

Wettability is more important for making hydrophobic / hydrophilic materials. LASERS are used for making colors, micro textures, etc. LASER power, type of LASER, interaction time, material plays a critical in LASER machining.

Questions from participants were taken by the Speaker, at the end of the session. Dr. Santhosh N, Associate Professor from Mechanical Engineering Department proposed the vote of thanks to Dr. J. Ramkumar, on behalf of MVJ College Management and Organizing Committee. The session concluded with feedback from the participants.

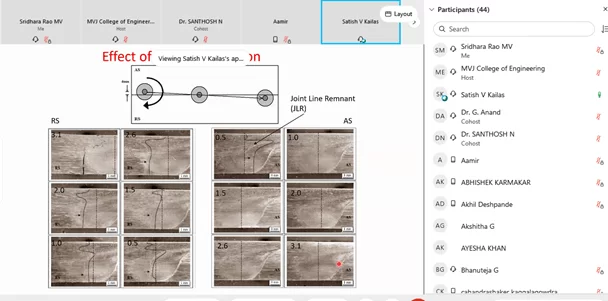

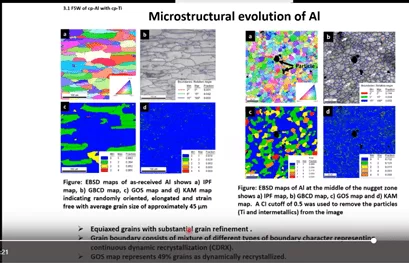

The second session on the first day was by Dr. Satish V Kailas, Professor, Dept. of ME, IISc Bangalore, who spoke on ‘Joining of metals using friction stir welding’.

Dr. Sunil Shankar Waddar welcomed all the participants for the second session on the first day of the STTP and introduced the Resource Speaker.

The importance of joining metals without soldering materials was highlighted. Friction stir welding provides an opportunity to join the metals without producing harmful gases and causing environmental pollution. Friction stir welding for joining of Cu was demonstrated by the Speaker. Microstructure evaluation of Aluminium alloys was also explained in detail.

Day 1 Session 2 : Joining of Metals by Friction stir Welding

The Speaker took Questions from participants, at the end of the session. Dr. Santhosh N proposed the vote of thanks to the Resource Person on behalf of MVJ College Management and the Organizing Committee. The session concluded with feedback from the participants.

Day 2: 2nd March, 2021 (Tuesday)

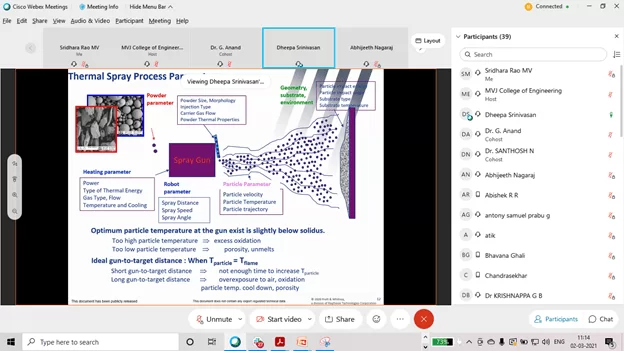

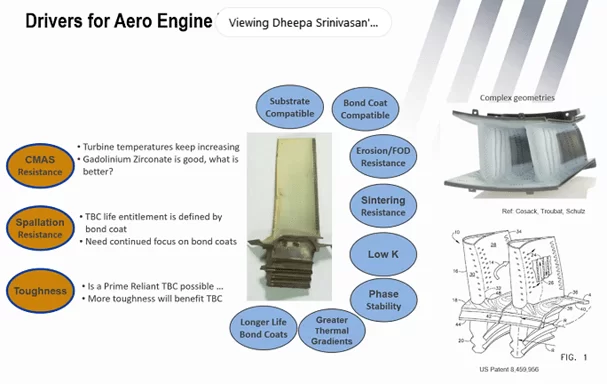

The first session on the second day was on ‘Advanced Coating Technologies for Gas Turbines’, by Dr. Dheepa Srinivasan, Chief Scientist from Pratt & Whitney, IISc Branch, Bangalore. Dr. Sangamesh Gondegaon, Associate Professor, Mechanical Engineering Department, MVJCE, welcomed the participants. Dr. Santosh N introduced the Resource Speaker to the participants.

Materials have played a key role in jet engine advancements, over decades. Core efficiency, fan weight and development, time, drive, materials, R&D etc. are important aspects. Oxidation coatings and thermal barrier coatings help the turbine blades to withstand up to 2700 F. Single crystal technology resulted in a paradigm shift in creep strength, thermal fatigue strength and corrosion resistance. Gadolinium Zirconium TBC results in significantly longer life than Yittria Zirconia in HPT blades for gas. All these valuable inputs were given by the Speaker.

Day 2 Session 1 : Advanced Coating Technologies for Gas Turbines

Turbine Applications and the role of coatings in gas turbine applications were explained in detail. Thermal spray coating process was also explained, elaborately, with examples. The topics of Thermal Barrier coatings and their application to Gas Turbine airfoils were also elaborated by Dr. Dheepa Srinivasan.

Day 2 Session 1 : Thermal Spray and Thermal Barrier Coatings

Questions from participants were taken at the end of the session. Dr. Santhosh N proposed the vote of thanks to the Resource Person, on behalf of MVJ College Management and the Organizing Committee. The session ended with feedback from participants.

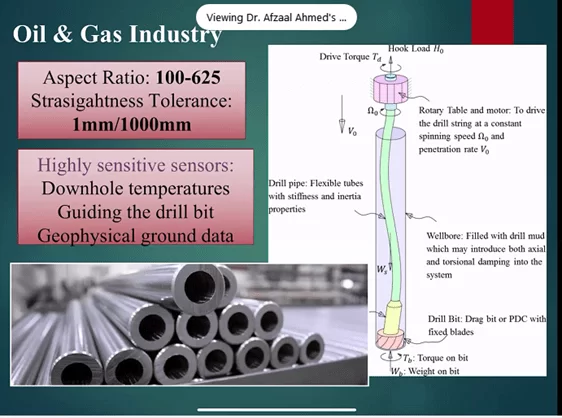

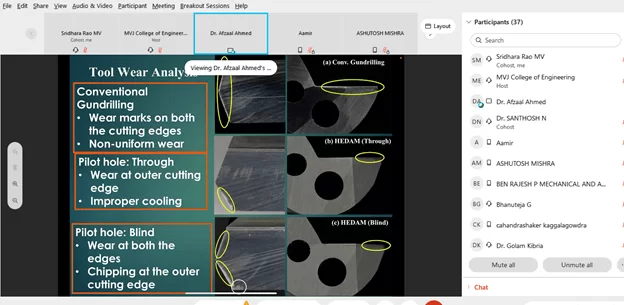

The second session on the second day was by Dr. Afzaal Ahmed, Assistant Professor, IIT Palakad, on the topic ‘Novel approach for drilling exotic engineering materials’. Dr. Sangamesh Gondegaon from Mechanical Engineering Department welcomed the participants for the third day of the STTP and introduced the Resource Speaker to the participants.

Challenges in deep hole drilling which are applicable in the Oil & Gas industry, automobile and defence industry were discussed. Cutting forces in deep hole drilling was elaborated with suitable annotations. New method, Hybrid Electric Discharge Arc Machining (HEDAM) to decrease tool bit erosion, maintaining straightness which increases drilling speed by 12 times were explained.

Day 2 Session 2 : Novel approach for drilling exotic engineering materials

Questions from participants were taken at the end of the session. Dr. Sangamesh Gondegaon proposed the vote of thanks to the Resource Person and the session concluded with feedback from the participants.

Day 3, 3rd March, 2021 (Wednesday)

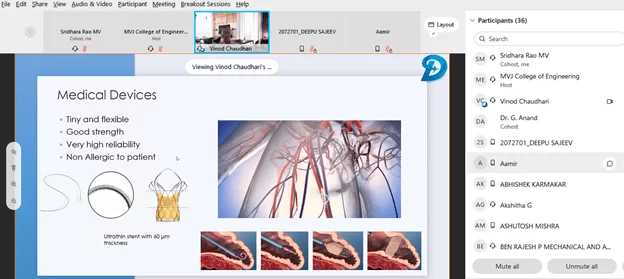

The first session on Day 3 was on the topic ‘Manufacturing advancement in medical technologies’ by Mr. Vinod Chaudhari, Technology Director, Dheya Engineering & Technologies, also the former Technical Leader, GE Aviation Bangalore. Mr. Sridhara Rao M V, Associate Professor in Mechanical Engineering Department, MVJCE, introduced the Resource Person to the participants.

Mechanical requirements for tiny medical devices used in cleaning of arteries and treating of heart blockages were explained in detail. The Speaker pointed out the scope for cost reduction of medical equipment by using advanced machining process. He also elaborated on the opportunities created to the Mechanical Engineering world, after the onset of the Corona Virus.

Day 3 Session 1 : Manufacturing advancement in medical technologies

Day 3 Session 1 : Manufacturing advancement in medical technologies

The Speaker took Questions from participants at the end of the session. Dr. Sangamesh Gondegaon proposed the vote of thanks to the Speaker, on behalf of MVJ College Management and the Organizing Committee. The session concluded with feedback from the participants. Overall, the session was well received by all the participants.

The second session of the third day was from Mr. B S Raghunandan, Technical Manager, Quest Global Services, Bangalore, on the topic ‘Digital Manufacturing’. Dr. Sangamesh Gondegaon welcomed the Speaker and all participants to this session. Dr. Santhosh N introduced the Resource Speaker.

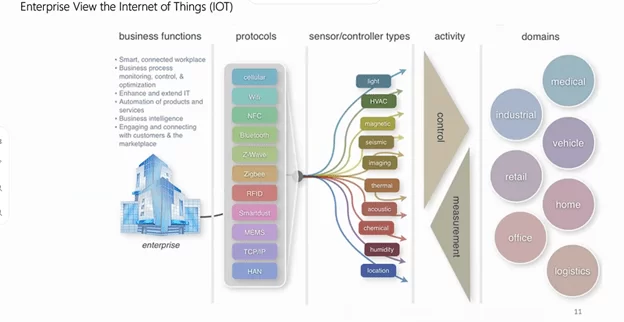

Day 3 Session 2 : Digital Manufacturing

IOT, its details and their implementation were discussed in this session. The requirement for Digital manufacturing and its impact were elaborated. The Speaker explained the role of Virtual Reality and Augmented Reality in the design of factory setups and process installation and maintenance, with interesting videos.

Questions from participants were taken at the end of the session. Dr. Sangamesh Gondegaon gave the vote of thanks, and thanked the Resource Person on behalf of MVJ College Management and the Organizing Committee. The session concluded with participants’ feedback.

Day 4, 4th March, 2021 (Thursday)

The first session of Day 4 started with Dr. Sunil Shankar Waddar welcoming all the participants and introducing the Resource Speaker. At this session, Dr. K. Niranjan Reddy, Scientist E, Precision Metrology, CMTI, Bangalore, spoke on ‘Advanced Mechanical Measurements for Precision Engineering’.

The Speaker explained about conventional devices for linear, angular measurements, using many illustrations. Different industry standards were explained in detail. Dr. K. Niranjan Reddy also spoke about different Optical instruments, viz, CMM, Interferometry devices for precision measurement, in elaborate detail. Laser trackers in Ultra precision measurement were explained, with test setups.

Day 4 Session 1 : Advanced Mechanical Measurements for Precision Engineering

Questions from participants were taken at the end of the session. Dr. Sunil Shankar Waddar proposed the vote of thanks, thanking the Resource Person on behalf of MVJ College Management and the Organizing Committee. This session too concluded with feedback from the participants.

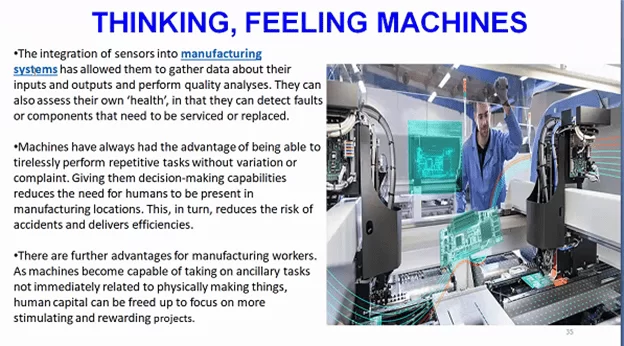

The second session on Day 4 was on the topic ‘Intelligent Manufacturing’, by Dr. R Elansezhian, Professor and Placement Officer, Dept. of ME, Puducherry Technological University, Puducherry.

Dr. Sunil Shankar Waddar welcomed all participants and Dr. G. Anand, Associate Professor, introduced the Resource Speaker.

Day 4 Session 2 : Intelligent Manufacturing

Dr. R Elansezhian started the session by explaining the differences between LEAN and Agile Manufacturing. He elaborated on the need for, and advantages of, Intelligent manufacturing in the scenario of the current industry revolution. The differences between smart and intelligent manufacturing were highlighted, with examples. Dr. R Elansezhian pointed out that it may take another 10 years to completely shift to the intelligent manufacturing paradigm at all levels globally, and realize its benefits. Manufacturing organizations that fail to implement these revolutionary technologies may be soon out of business as they will be highly vulnerable to competition.

Questions from participants were taken by the Speaker, at the end of the session. Dr. Santhosh N proposed the vote of thanks to the Resource Person, on behalf of MVJ College Management and the Organizing Committee. The session concluded with feedback from participants, as usual.

Day 5: 5th March, 2021 (Friday)

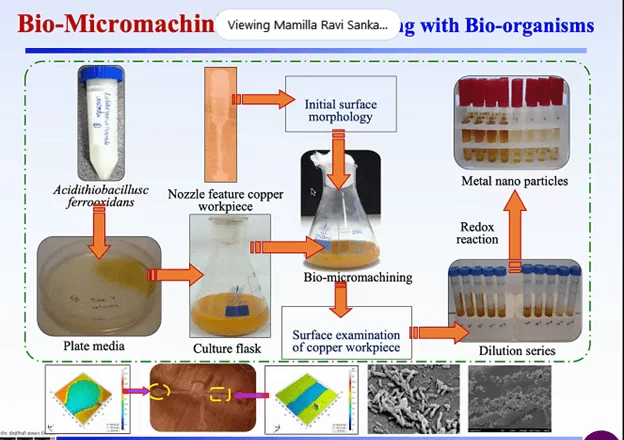

The first session on Day 5 was on the topic ‘Smart Abrasive flow nano finishing of bio medical implants’, by Dr. Mamilla Ravishankar, Associate Professor, Dept. of ME, IIT Tirupati. Dr. G. Anand introduced the Resource Person.

Day 5 Session 1: Smart Abrasive flow nano finishing of bio medical implants

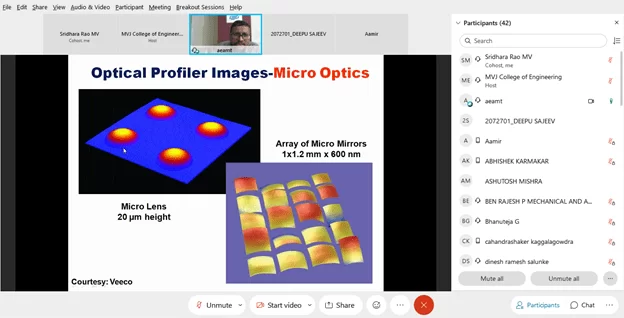

Dr. Mamilla Ravishankar discussed micro machining applications in biomedical, nuclear, micro fluidic channels for MEMS applications. Laser micromachining for automobiles, micro nano coatings were also elaborated in detail.

After the Speaker took the Questions from the participants, Dr. Sunil Shankar Waddar gave the vote of thanks, thanking the Resource Person on behalf of MVJ College Management and the Organizing Committee. The session concluded with feedback from participants.

The second session on Day 5 was on the topic ‘Precision High speed green (dry/near dry) machining of aerospace materials’, by Dr. Dinesh Singh Thakur, Head, ME Department, DIAT (Defence Institute of Advanced Technology), DRDO, Pune.

Dr. Sunil Shankar Waddar welcomed all participants to the fifth day of the STTP, and introduced the Resource Speaker.

Day 5 Session 2 : Precision High speed green (dry/near dry) machining of aerospace materials

In this session, the Speaker highlighted the importance of micromachining for aerospace applications. Understanding of physics helps researchers to develop innovative methods. Dr. Dinesh Singh Thakur explained about green machining (coolant fluid elimination) techniques and demonstrated sheet metal cutting operations. High speed machining for Aerospace materials was also explained in detail.

Questions from participants were taken at the end of the session, after which Dr. Sunil Shankar Waddar thanked the Resource Person, on behalf of MVJ College Management and the Organizing Committee. Lastly, feedback was taken from the participants.

Day 6: 6th March, 2021 (Saturday)

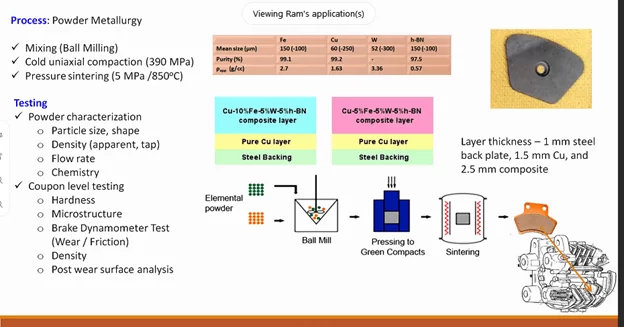

The first session on the sixth day was on ‘Functional graded Cu-Fe-W-hBN based composites for Brake pads and possible funding & Ph.D proposal ideas’, by Dr. Ram Prabhu, Deputy Director / Scientist, CEMILAC, DRDO, Bangalore. Dr. Sunil Shankar Waddar welcomed the Speaker and all the participants to the first session of the last day of the STTP. Dr. Santhosh N introduced the Resource Speaker.

Day 6 Session 1 : Functional graded Cu-Fe-W-hBN based composites for Brake pads

The Speaker explained about the different layers of material on brake pad, material composition and powder metallurgy process. The influence of different constituents on mechanical properties were also explained in detail. Powder processing methods and characterization procedure were elaborately dealt with. Lastly, the Speaker gave insight into possible research proposals and PhD opportunities useful for industry, before taking Questions from the participants.

Dr. Sunil Shankar Waddar delivered the vote of thanks to the Resource Person, on behalf of MVJ College Management and the Organizing Committee. The session concluded with feedback from the participants.

The second session on Day 6 was on the topic ‘Advanced Machining Process – Micromachining', by Dr. Somashekhar Hiremath, Professor, Dept. of ME, IIT Chennai. Dr Sunil Shankar Waddar introduced the Speaker to the participants.

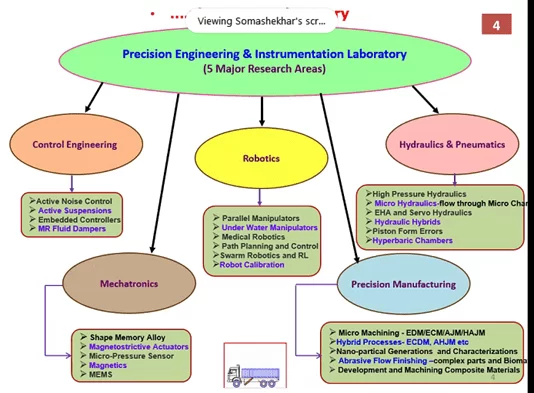

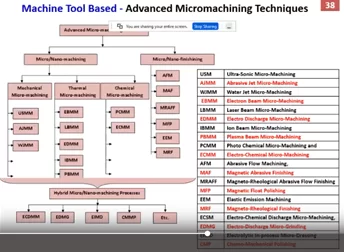

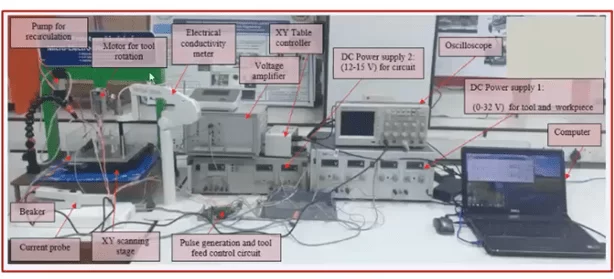

Dr. Somashekhar Hiremath started his lecture by highlighting the role of miniaturization of products and processes. He then discussed possible Research areas in Control Engineering, Mechatronics, Robotics, Precision Manufacturing & Hydraulics and Pneumatics. Robotic calibration test facility used for Workspace calibration, Dynamic characteristics in Robotic system was also discussed. Different Micromachining processes like EDM, ECDM, Abrasive Jet Machining were explained, with fundamental principles and test setups. Last but not the least, the Speaker gave inputs on Micro channel machining, Micro Electric Mechanical Systems (MEMS).

Day 6 Session 2 : Advanced Machining Process - Micromachining

Miniaturization increases the overall system efficiency and ease of transportation, occupies less space and requires less material. Different micro machining methods, viz, subtractive process, additive 3D printing, Deep X-ray Lithography, nano finishing, mass containing and joining were elaborated by the Speaker.

Advancements and research opportunities in micro-feature generation, building a microstructure for biomedical applications, nano particle generation and building a mathematical model and use of artificial intelligence were explained in detail, Research scholars and faculty should take up projects based on these topics.

Questions from participants were taken at the end of the session. Principal, MVJ College of Engineering, proposed the vote of thanks to the Resource Person on behalf of MVJ College Management and the Organizing Committee. The session concluded with feedback from participants.

FDP Culmination

The STTP came to an end at the end of six days, after featuring 12 sessions from different expert speakers from Academia and Industry. Dr. Vivenkanand Huddar, the HoD of Mechanical Engineering Department, MVJCE, summed up the importance of the different sessions and the valuable inputs and knowledge shared by all the speakers. Mr. Sridhara Rao MV, Associate Professor, Mechanical Department, presented glimpses of all the sessions, from Day 1 to Day 6. The Principal, MVJCE, provided the concluding remarks, and thanked each and every Speaker for accommodating the sessions in the midst of their busy schedules. The STTP concluded with vote of thanks to the Management of MVJCE, Organizing Committee, Resource Speakers and all participants. Feedback was taken and Quiz sessions were conducted at the end of the 6th day.

Outcome of the STTP:

It has enlightened the participants about advancements in precision manufacturing industry, digital manufacturing, different kinds of materials for strategic applications and 3D printing for medical implants. Several interesting research areas in micro-machining and nano-finishing, surface texturing and coloring using LASERS, powder metallurgy processes and characterization came up during the discussions, and these can be taken forward.